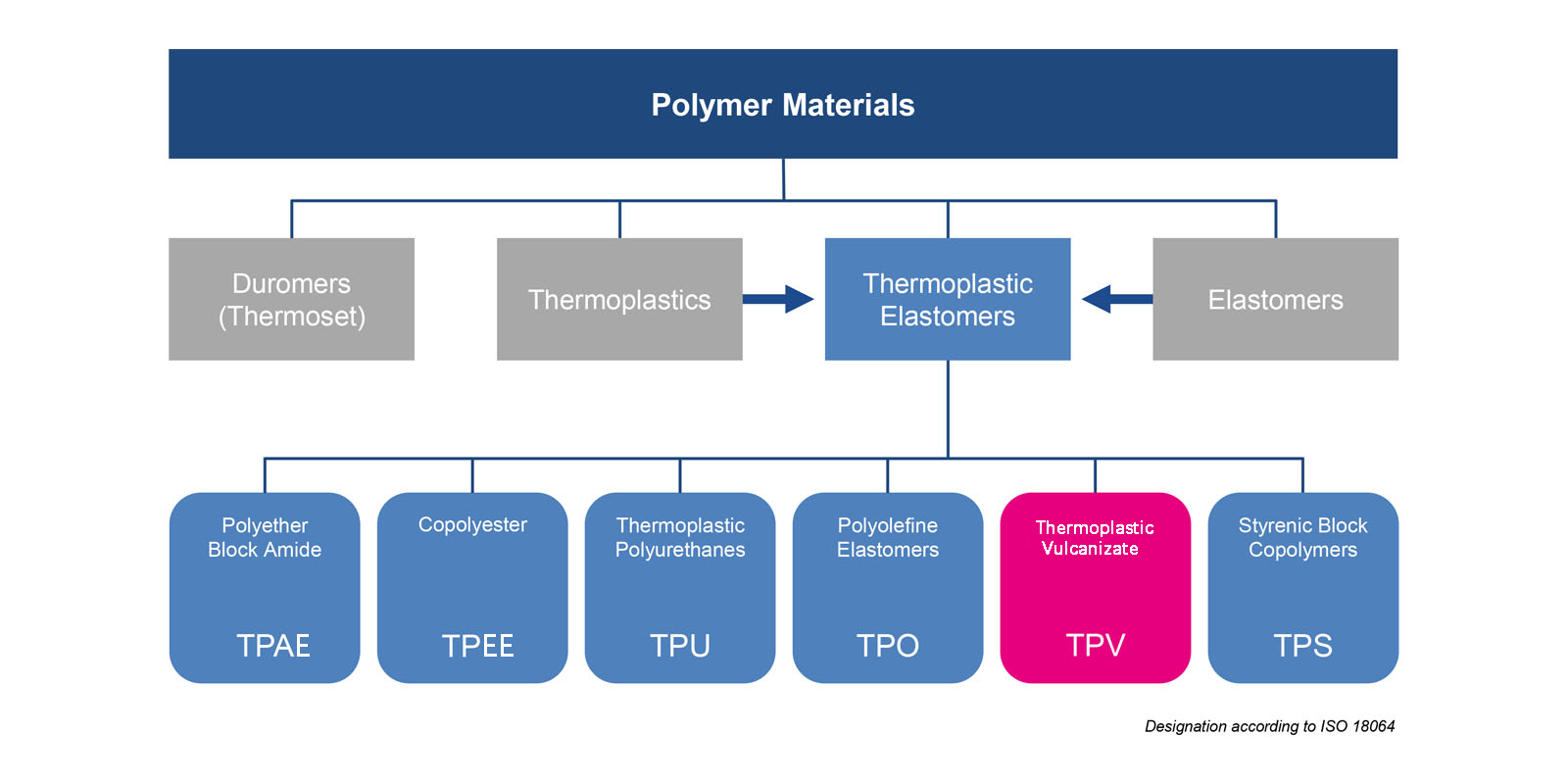

Thermoplastic styrene block copolymer (TPS) describes a subgroup of thermoplastic elastomers (TPE).

TPS products are composed of at least three block copolymers of styrene and specific dienes, with two end segments being polystyrene and the internal soft segments being polydiene or hydrogenated polydiene.

Unlike TPA, TPC, and TPU, TPS materials are not considered reactor products. TPS is a compound - which means manufacturers melt and homogenize various raw materials in the extruder system. In the case of TPS, different SBC polymers are mixed with thermoplastic plastics. The uniform mixing of thermoplastic components and soft components (SBC) produces typical material properties of TPS, so they can be processed in subsequent injection molding or extrusion processes. The selection and mixing ratio, together with other components such as fillers, process oils, and additives, determine the performance of the corresponding compound.

The mixing and composite process of SBC polymer with other polymer materials and components provides manufacturers with almost unlimited possibilities: the development of new formulas depends on the use of raw materials and also on the mixing ratio. This diversity can even be extended: with the help of special additives and fillers, polymer blends can exhibit properties such as conductivity and even flame retardancy.

In addition, the production process itself and the conditions applied also have a significant impact on the properties and properties of TPS materials.

Thermoplastic elastomers (TPE) are produced in particle form and delivered to customers. Sungallon TPE particles can be processed without adding other substances. There are multiple ways to address these issues. The most commonly used methods include injection molding and extrusion processes. However, thermoplastic elastomers can also be blown or processed using 3D printing.

Depending on the formula and performance, materials can be combined with other materials through multi-component injection molding and co extrusion processing. Sungalon TPE's products are bonded to engineering plastics such as polypropylene (PP), polyethylene (PE), polystyrene (PS), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), styrene acrylonitrile copolymer (SAN), and polybutylene terephthalate (PBT). Polyamides (such as PA6, PA66, and PA12) can also achieve excellent bonding effects.

The successful cases of thermoplastic elastomers are largely based on the advantages of multi-component injection molding. TPE compounds can be processed like plastics, but have the characteristics of elastomers. This fact enables efficient processing in large quantities, especially with the use of multi-component technology.

Due to their physical cross-linking, thermoplastic elastomers can always melt and return to the processing chain. In the selected application, it is usually recommended that customers add up to 15% of the raw material for recycling the starting material and gate.

In addition, Sungalon TPE is intensifying the development of new formulas, in which recycled materials have been used in the production process. The first recycling series has been included in the investment portfolio, and projects in the automotive and industrial sectors have been successfully implemented.

Since 1999, Sungalon TPE has been developing and producing thermoplastic elastomers based on styrene block copolymers. In the past few decades, Sungalon TPE has accumulated extensive professional knowledge and is able to expand its product portfolio, which is mainly composed of TPS materials and has rich experience, always focusing on current customer and market needs. The company is tailor-made with high precision and can adjust products according to specific customer requirements.

With a strong market positioning and a special market team, Sungalon TPE develops and produces high-quality compounds for the automotive industry, industrial, and consumer applications worldwide. Sungalon TPE also provides fully approved investment portfolios for highly sensitive medical and pharmaceutical markets.